Laminar air flow stations are built with respect to the type of process being performed.

Laminar Flow Benches and Booths – these are larger designs typically designed for larger manufacturing processes. Laminar Flow Cabinets and Hoods – these are the housings manufactured to create the controlled air environment. The constant flow of filtered air provides material and product protection. Horizontal Laminar Flow Cabinets – Horizontal Laminar Flow Cabinets where air flow originates from above the work area but then changes direction and is processed across the work area in a horizontal direction. Vertical flow cabinets typically provide more protection for the booth/cabinet operator because the air can be directed away from the operator. The air can leave the working area via holes in the base. Vertical Laminar Flow Cabinets – Vertical Laminar Flow Cabinets function much like horizontal Laminar Flow Cabinets, however, in vertical setups the laminar air is directed vertically downwards onto the working area. Laminar air flow systems are usually cabinet-based, but may be designed to be a booth or work bench or even a room as well. Laminar air flow systems – these are mechanical systems manufactured to provide laminar air flow in a large or small area to perform certain tasks in an environment of constant non-turbulent air flow. Laminar flow is a flow regime characterized by high momentum diffusion and low momentum convection.” – Wikipedia

“In laminar flow, the motion of the particles of the fluid is very orderly with particles close to a solid surface moving in straight lines parallel to that surface.

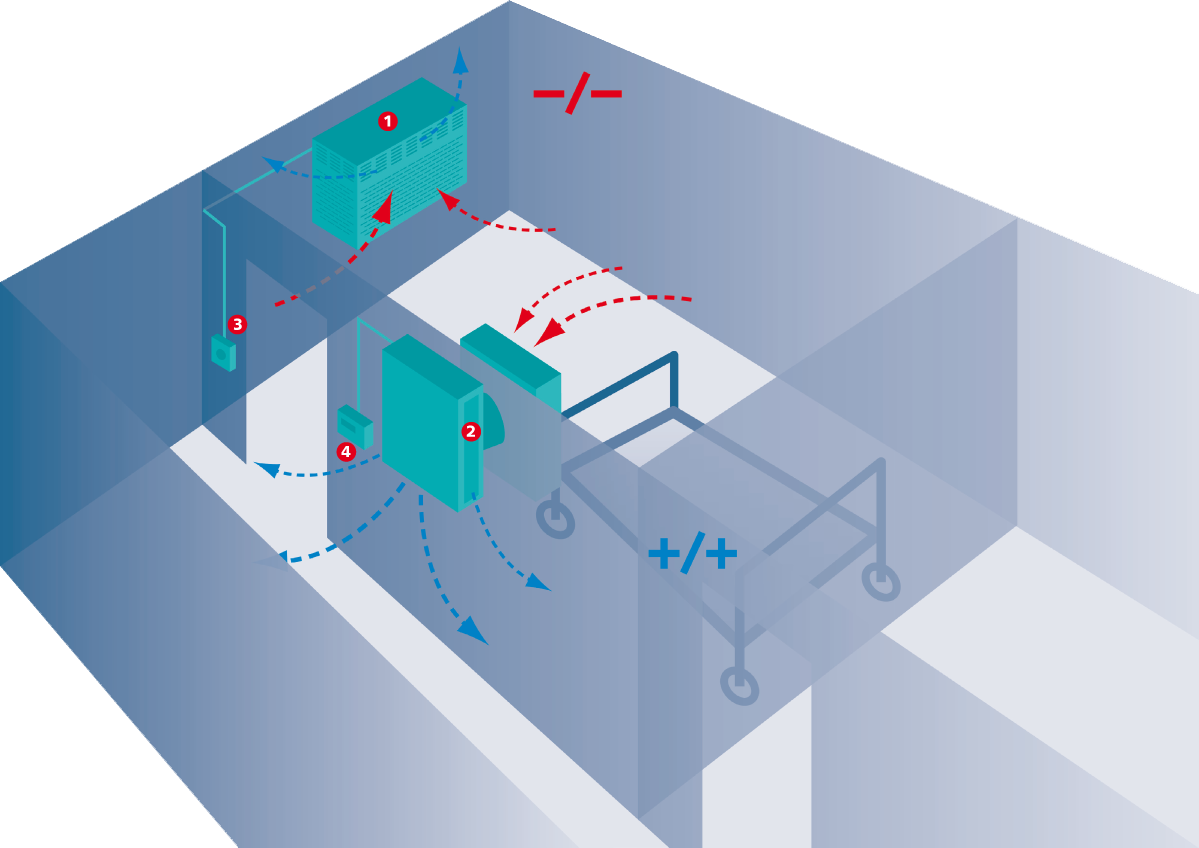

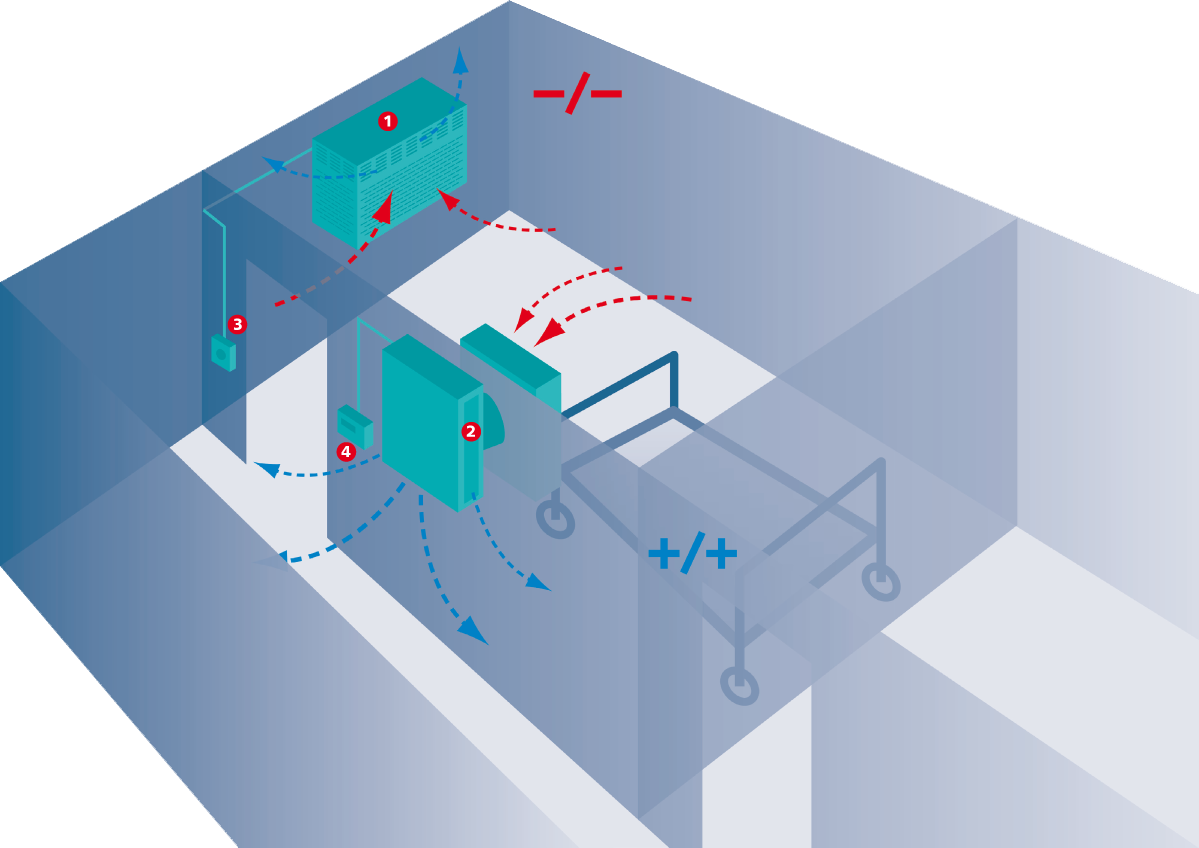

Laminar air flow: principle – Laminar air flow is a process where air is manipulated to force air to move at the same speed and in the same direction, with no or minimal cross-over of air streams in a given space. The best way to understand laminar air flow is to first differentiate between laminar air flow as a principle and laminar air flow in use as a system. Laminar air flow principles and Laminar air flow systems are commonly used in cleanrooms, positive and negative pressure rooms and other sensitive controlled environments. Laminar Air Flow Systems – General Terminology

0 kommentar(er)

0 kommentar(er)